Motor Supply Connector

DANGER: Shock and Fire Hazard!

Electrical wiring must be designed and installed in accordance with local electrical safety regulations to prevent the risk of fire and electrical shock.

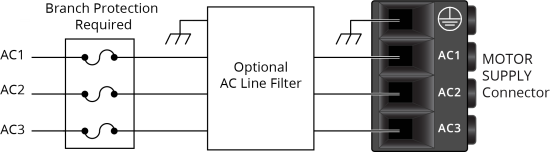

Motor power is applied to the AC1, AC2, and AC3 terminals of the Motor Supply connector. Three phase power is required and must be in a center grounded TT/TN configuration. For CE compliance, connect an AC line filter as close as possible to the drive (refer to Minimizing Noise for EMC/CE Compliance).

The system designer must provide branch protection (fuses or circuit breakers) for the

A line reactor can be used to reduce inrush currents, reduce conducted harmonics, improve power factor and protect the drive against voltage surges. Refer to Inrush Current Limiting for more information on reducing inrush currents.

CAUTION: The drive can cause a DC current in the protective earthing conductor. Where a residual current-operated protective (RCD) or monitoring (RCM) device is used for protection in case of direct or indirect contact, only an RCD or RCM of Type B is allowed on the supply side of the drive.

WARNING: Verify that all ground connections are installed correctly before you apply power to the iXC6e/XC6e.

Figure 2-2: Motor Supply Connections

Table 2-3: Motor Supply Connector Pinout

|

Pin |

Function |

|---|---|

|

AC1 |

AC Motor Power Input |

|

AC2 |

AC Motor Power Input |

| AC3 | AC Motor Power Input |

|

|

Protective Earthing Conductor: 2.5 mm2 (14 AWG) minimum conductor size |

Use these parameters to configure motor overload protection: AverageCurrentThreshold, AverageCurrentTime, and MaxCurrentClamp.

Table 2-4: Motor Supply Mating Connector Ratings

| Specification | Description | |

|---|---|---|

| Type | 4-Pin Terminal Block | |

| Part Numbers | Aerotech: ECK02495 | |

| Phoenix: 1710352 | ||

|

Conductor Cross Section |

One conductor, stranded with ferrule and plastic sleeve | 8...14 AWG (2.5...10 mm2) |

| Two conductors (same cross-section), stranded, twin ferrule with plastic sleeve | 10...14 AWG (2.5...6 mm2) | |

| Tightening Torque | 1.7...1.8 N·m | |

| Conductor Insulation Strip Length | 12 mm (0.5 in) | |

|

(1) Refer to the manufacturer website for additional information. |

||