Inrush Current Limiting

A large current can occur on the motor supply lines when power is first applied to the drive. This current is due to charging of the internal motor supply capacitance and can cause the circuit breakers to open unexpectedly.

Inrush limiting devices, such as Negative Temperature Coefficient (NTC) devices, can be installed externally to the drive to reduce this current. NTC devices can be inserted into each motor AC supply line. Ideally these devices are bypassed using a contactor shortly after power has been applied and the capacitors are fully charged. This helps to keep the NTC device cool so that it is effective on future power up events and also provides maximum stiffness of the motor supply voltage. Alternately, high surge power resistors can be used to further reduce the inrush current levels.

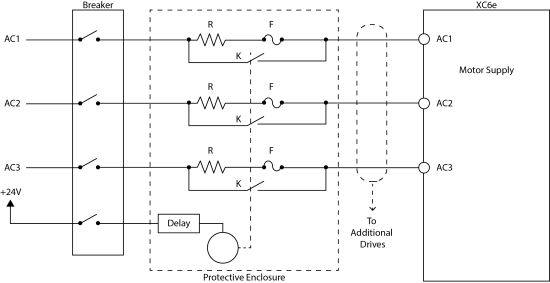

The figure that follows shows a typical configuration of an inrush limiting circuit implemented external to the drive.

Figure 2-3: Inrush Limiting Circuit External to Drive

Inrush Limiting Device (R)

The inrush current is given by the equation that follows, assuming that 3 limiters are used, one per phase.

| Iin | = Vin · (√2/√3) / R | |

| Where: | ||

|

Iin |

= peak inrush current A | |

|

Vin |

= line-line input voltage (RMS) | |

|

R |

= resistance of the limiting device in Ohms | |

If only two limiters are used, the inrush current increases by a factor of 3x in the worst case. See the examples that follow for calculating the inrush current while using different limiting devices.

Example 1

Ametherm: MM35 1R550-DIN (1.5 Ohm, 1200J, 50A - NTC device) with 208VAC Motor Supply input voltage

Based on the energy rating on this device, it can support up to twelve 240 V XC6e drives and up to nine 480 V XC6e drives.

| Ipk |

= 208 · 0.816 / 1.5 |

|

| = 113 A | ||

Example 2

Vishay: RBEF02208R000KFBVT (8 Ohm 220W resistor) with 480VAC Motor Supply input voltage

The RBEF type resistor is a high surge resistor type that can be used to further reduce inrush currents. Installing the resistors in a separate protective enclosure is recommended to reduce the risk of fire and electric shock. You should also consider adding fuses in series with the resistor and monitoring the bypass relay contactor for failure.

| Ipk |

= 480 · 0.816 / 8 |

|

| = 49 A | ||

Contactor K/M

A bypass contactor is required when using resistors, and it is recommended when using NTC limiters. The required time delay can be calculated using the formula that follows with a Tc (time constant) factor between 5 and 10.

| Td | = TC· Req· Ceq· N | |

| Where: | ||

|

Td |

= Time delay required in seconds | |

|

TC |

= Time constant factor (5-10) | |

|

Req |

= Inrush limiter resistance | |

|

Ceq |

= Internal capacitance of each drive (refer to Electrical Specifications (by Ordering Option)) | |

|

N |

= Number of drives | |

See the examples that follow that show how to correctly calculate the Td (time delay).

Calculate the contactor delay time for four 480 V XC6e drives using three 8 Ω inrush limiters.

| Td(min) | = 5· 8· 1500· 10-6· 4 | ; Tc = 5 |

| = 0.24 s | ||

| Td(max) | = 10· 8· 1500· 10-6· 4 | ; Tc = 10 |

| = 0.48 s |

Calculate the contactor delay time required for six 240 V XC6e drives using three 1.5 Ω inrush limiters.

| Td(min) | = 5· 15· 4800· 10-6· 6 | ; Tc = 5 |

| = 0.22 s | ||

| Td(max) | = 10· 15· 4800· 10-6· 6 | ; Tc = 10 |

| = 0.44 s |

The list that follows includes suggestions for inrush limiter bypass contactors. You can also use devices that are not on the list, but they must be rated for the system voltage / current and must be in accordance with local electrical safety requirements.

| Manufacturer P/N | Description |

|---|---|

| CA7-40-E-M40-24E | 4 Pole, 37A, 24VDC coil |

| CA7-60D-00-24DD | 3 Pole, 60A, 24VDC coil |

| CA7-72D-00-24DD | 3 Pole, 60A, 24VDC coil |

| CA7-85D-00-24DD | 3 Pole, 60A, 24VDC coil |

| CA7-97D-00-24DD | 3 Pole, 60A, 24VDC coil |

The list that follows includes time delay accessories for the CA7 series contactors. The contactor may also be controlled by software or other logic that monitors the motor supply levels and provides the desired delay.

| Manufacturer P/N | Description |

|---|---|

| CRE7-3-24/48VDC | 0.1 to 3 second adjustable turn on delay |

| CRE7-30-24/48VDC | 1 to 30 second adjustable turn on delay |