Axis Updates and Parameter Calculations in Machine Setup

You can use Machine Setup to make updates to existing axes, and in some special cases, Machine Setup will calculate new values only for parameter subsets that changed because of the updated axis. These limited parameter updates only occur on the axis that the change is made to. Parameters that were not set with Machine Setup will stay the same.

See the Making More than One Change to an Axis section for information on changing different parts of an axis at the same time.

Limited Parameter Updates

The list that follows includes axis changes in which Machine Setup updates limited subsets of parameters.

Tip: The Summary milestone at the end of Machine Setup shows a full list of parameter changes. In the Details column, click on the View Changes link for details.

If you select a new lens option for a galvo laser scanner device in the Mechanical Devices milestone and the Effective Focal Length or Nominal Field Size change, Machine Setup calculates new values for related parameters.

If you change some part of the primary and/or auxiliary feedback device in the Mechanical Device or Interconnectivity milestones but do not change any other parts of the device, Machine Setup calculates new values for related parameters.

If you change the user units in the Interconnectivity milestone by selecting a new unit or clicking the Inverted toggle on or off, Machine Setup calculates new values for the CountsPerUnit parameter.

If the CountsPerUnit parameter is updated this way in Machine Setup, existing parameter values that use user units are scaled by the ratio of the old CountsPerUnit parameter value and the newly calculated CountsPerUnit parameter value. This keeps all manual adjustments that you possibly made to these parameter values by scaling them.

This change only applies to the spar axis of a gantry system. See Changing Units on a Gantry Spar for more information.

If you do not make changes to a previously configured axis, Machine Setup will not calculate new parameters. This keeps all of the parameter values that were set on the axis before this Machine Setup session.

This lets you configure new axes without losing work on existing axes.

Calculating New Parameters

There are three cases in which Machine Setup will calculate a new set of parameters for your axis:

-

The axis was not defined the last time that you completed Machine Setup. This occurs when Machine Setup is used for the first time or when you add new axes to a system.

-

The axis changes in a way that is different from the changes noted in the Limited Parameter Updates section. For example, new parameters will be calculated if you replace a mechanical device with a device that is in a different category.

-

If you do not use the recommended calculations after you make a change that would be specially handled by Machine Setup, new parameters will be calculated.

When Machine Setup calculates new parameters, existing parameter values will not be saved or adjusted. For example, parameter values that were set by tuning operations or other methods that are external to Machine Setup will be gone. If you want Machine Setup to calculate new parameters while keeping some existing parameter values, use the detailed view of parameter changes in the last step of the Summary milestone. See the Summary section on the Machine Setup page for more information.

Making More than One Change to an Axis

All recommended calculation sets are mutually exclusive with other recommended calculation sets. If you make more than one change to an axis in just one Machine Setup session, only the most important change will apply. The other changes will not be on the axis after Machine Setup is completed nor will the other changes be used when calculating related parameters. The list that follows shows the importance levels of the three changes:

-

Galvo lens change

-

Feedback device change

-

User units scaled

If you have to make more than one change on the same axis, you must do so with more than one Machine Setup session so that you can save your updates and not lose parameter calculations. Use the steps that follow as a guideline when making more than one change:

-

Launch Machine Setup and make the most important change.

-

Complete Machine Setup to apply your change and the new parameter values.

-

Launch Machine Setup again and make the next most important change.

-

Complete Machine Setup to apply your change as well as the new parameter values that are calculated.

-

Do steps 3 and 4 until you have applied all of your changes.

Changing Units on a Gantry Spar

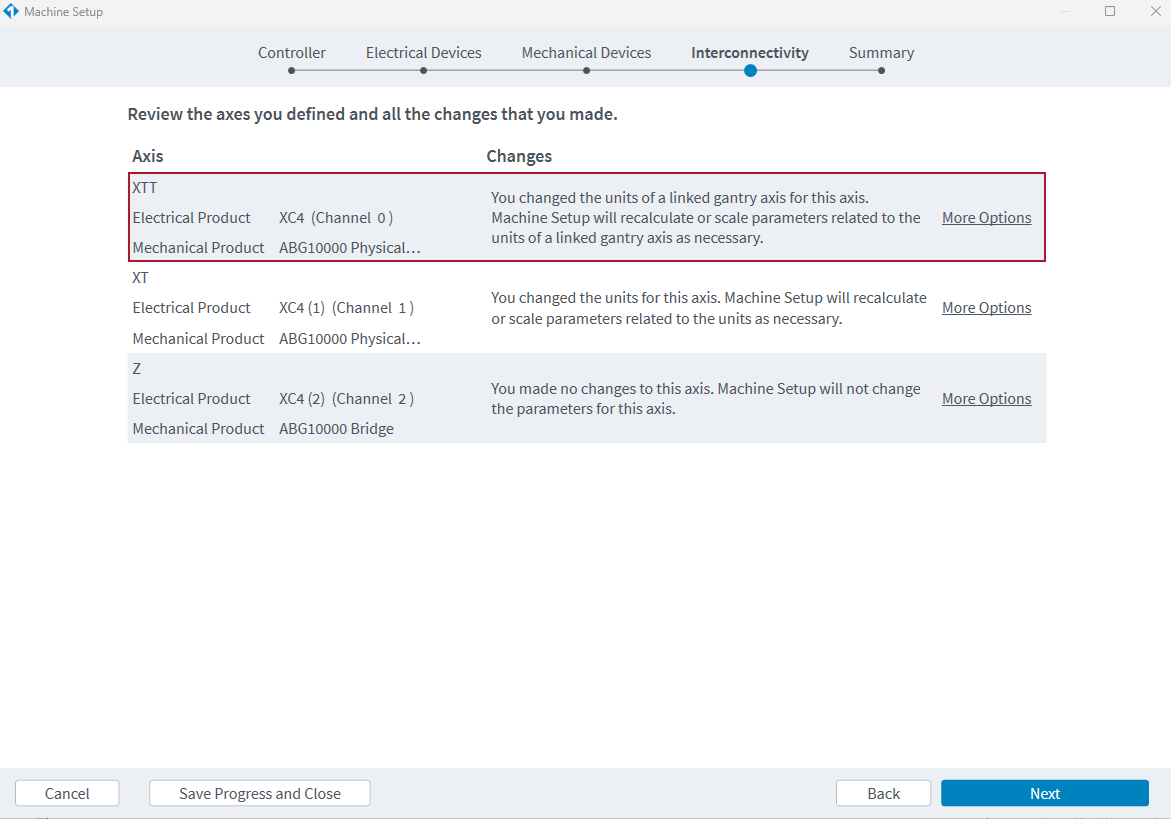

You can use the Interconnectivity milestone in Machine Setup to change the units or unit direction of a gantry spar for gantry axes that you have already configured. When you do this, Machine Setup calculates new parameter values for both spars because they are connected. The figure that follows shows the summary page after a user changes units on a linked gantry axis.

When you make unit changes for Decoupling Control setups, Machine Setup updates the GantryPhysicalDirection and ReverseMotionDirection parameters. When you make unit changes for Current Command Coupling Control setups, Machine Setup updates the CurrentCommandCouplingFollowerDirection parameter.

Making More than One Change on Gantry Spar Axes

You can make unit changes to one or both spar axes in one Machine Setup session. Machine Setup will update parameters for both spars as necessary.