Servo Tuning

IMPORTANT: This servo tuning guide does not apply if you are using stepper motors.

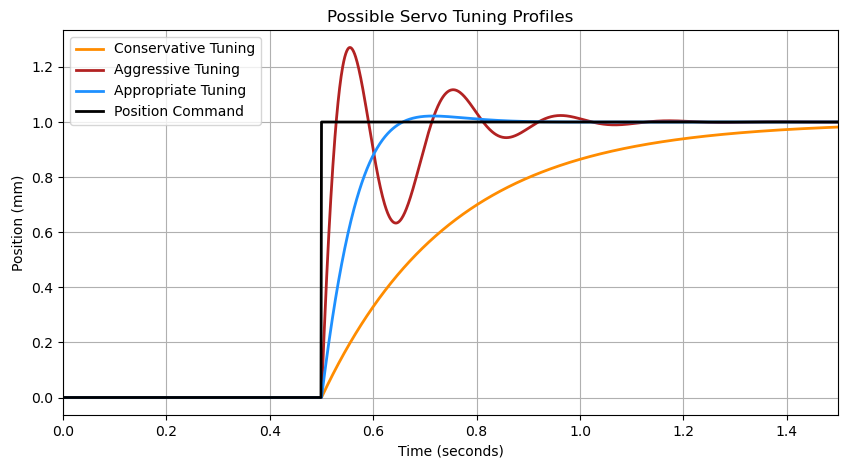

The Automation1 controller uses axis feedback to control the positioning accuracy and dynamic response of precision motion stages. The typical feedback control strategy for Aerotech products is a lead-lag implementation of a proportional-integral-derivative (PID) compensator. When you do servo tuning, you will adjust servo parameters to define the response to motion commands, errors, and disturbances. The tuning process has trade-offs between dynamic performance and servo stability. This guide shows you how to select the correct parameters for your application.

If you make changes to the servo parameters, they can have a large effect on how the axis responds to position commands. In the